NYK and MTI Develop Electronic UMS Check System

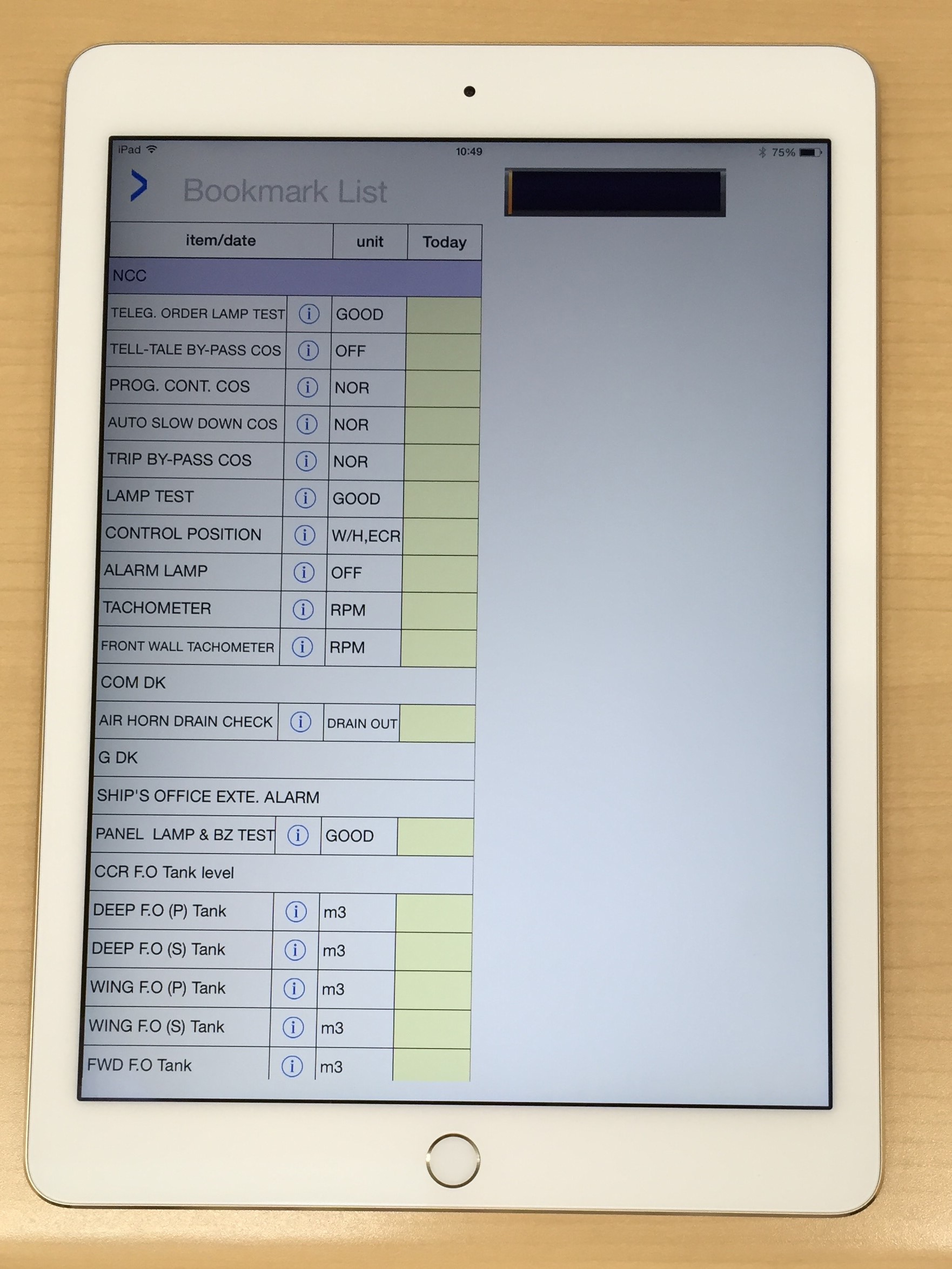

Nippon Yusen Kabushiki Kaisha (NYK) and MTI have jointly developed an electronic Unmanned Machinery Space (UMS) checklist and its operational system, the first time a Japanese shipping company has developed such a system.

Before an engine plant and equipment are operated unattended (e.g., at night), measurements need to be made, and taking such measurements is called a “UMS check.” In a conventional UMS check, the person in charge monitors equipment by conducting a large number of checks, manually recording the collected data on paper. But using the electronic checklist improves operational efficiency, and the collected data is also expected to be utilized as part of Big Data.

This new electronic UMS checklist has been specialized for mobile devices, and the NYK Group aims to introduce it aboard its owned vessels by the end of this year. As this development can be widely applicable to other onboard checklists, the NYK Group will continue its efforts to improve operational efficiency and safety management. System features are as below.

Features of the Electronic UMS Check System

| Functions | Advantages | |

| 1 | Paperless | No need for recording on paper |

| 2 | Numeric keypad exclusive to UMS check | Significantly reduces data-entry time compared to entry with a conventional keypad |

| 3 | Warning alarm when abnormal figures entered | – Notifies operator if abnormal figures are entered, allowing the operator to quickly respond – Helps crew to quickly become aware of abnormalities, and is thus a useful training tool too |

| 4 | Data trends graphically displayed | Data trends displayed as graphs, allowing chronological changes to be confirmed |

| 5 | Photos and video stored | Allows storage of photos or video of irregular equipment condition |

| 6 | Broadband transmission |

Transmits data directly from the mobile terminal to onshore servers, allowing onshore staff to browse data in a timely manner |

You can access a full version of this NYK news release from here