The NYK Group Starts Verification of Advanced Condition-based Maintenance for Autonomous Ships

The NYK Group has concluded a joint research agreement for developing advanced condition-based maintenance (CBM),* a new maintenance and management process for ship machineries, and has started verification during actual ship operation.

Machinery plant data from many sensors will be shared and monitored with the classification society and engine manufacturers in real time, thus advancing maintenance management. In the future, the NYK Group use this data and real-time monitoring to develop an advanced CBM to realize manned autonomous vessels.

Background

In the shipping industry, time-based maintenance (TBM) is usually practiced, but TBM requires a vessel to halt operations for a few weeks of inspections every two or three years even if no fatigue or breakdown of the engine is observed. Moreover, unexpected failures can occur during voyages and cause long delays.

In accordance with recent developments in information and communication technology, large amounts of data can be transmitted between ship and shore. The NYK Group has utilized these advancements to focus on CBM and conduct research on optimal maintenance. The NYK Group has now decided to boost its research by partnering with the companies indicated below to develop advanced CBM.

Outline of Joint Research

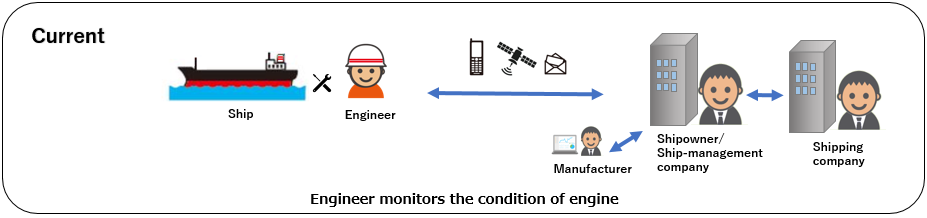

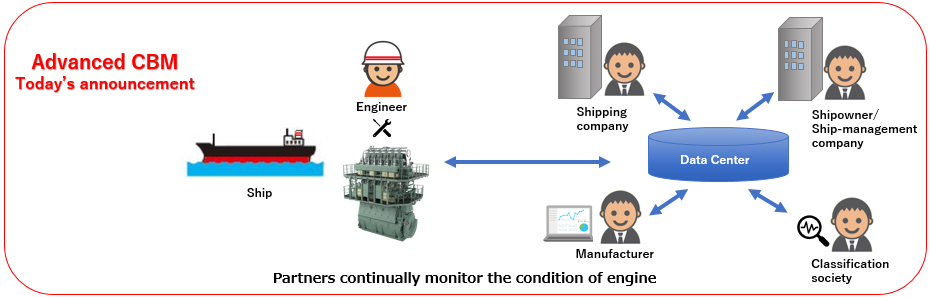

In addition to SIMS2,** a new sensor and equipment are installed in two different types of main engine and main steam turbine, and detailed operational data such as vibration and temperature of bearing are to be collected. The condition of the engine will then be shared and constantly monitored by the classification society and engine manufacturers.

The projects will also work to make failure predictions and remaining useful life (RUL) for the engine by taking advantage of manufacturer expertise to create optimal CBM guidelines and then verify them on actual ships.

These results will be shared with the classification society to establish a new classification survey scheme based on CBM.

| Projects | Partners |

| Joint research for realizing CBM for main diesel engines | NYK, MTI, Class NK, Japan Engine Corporation |

| Joint research for realizing CBM for main steam turbines | NYK, MTI, Class NK, Mitsubishi Heavy Industries Marine Machinery & Equipment Co. Ltd. |

Future

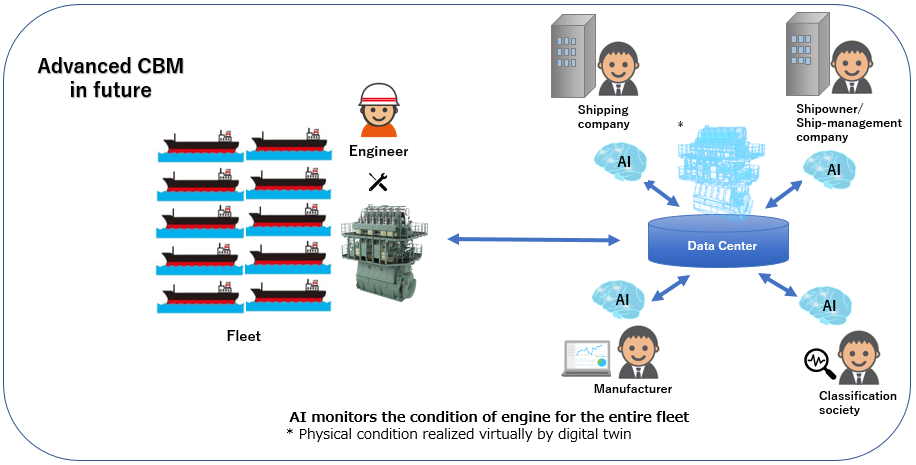

The NYK Group will improve the accuracy of failure predictions and remaining useful life (RUL). In the future, the Group will develop more advanced CBM that enables continuous monitoring of the condition through AI (artificial intelligence), and then realization of further optimal maintenance by combining information such as operational schedules.

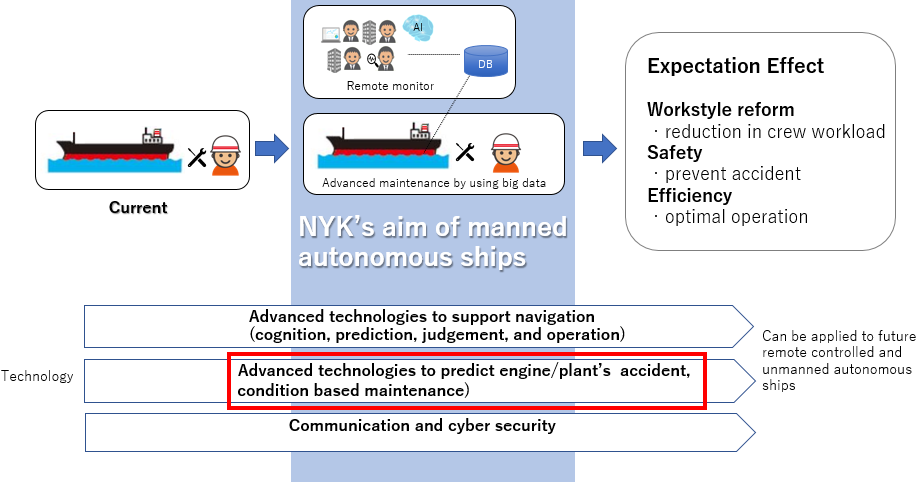

Establishing an advanced CBM system is a step toward a highly automated vessel, and thus an autonomous one.*** An innovative method that can greatly benefit the realization of manned autonomous vessel is the NYK Group’s target.

In accordance with its medium-term management plan “Staying Ahead 2022 with Digitalization and Green,” the Group is promoting digitalization initiatives, and strives to enhance innovation in the shipping industry with various partners making use of operational big data.

■Image of advanced CBM

* Condition-based maintenance (CBM)

A maintenance strategy that monitors the actual condition of an asset to determine what maintenance needs to be done and when, rather than after machinery failure or conducting maintenance on a regular basis.

** SIMS2

A ship information management system developed by NYK and MTI and allowing data-sharing among workplaces on land and sea in real time.

*** Manned autonomous ships

NYK’s aim of manned autonomous ships that will make use of advanced technologies and remote support from office to support ship operation and enhance safety.