Main Bearing CBM of Diesel Main Engine

October 3, 2022

Condition Based Maintenance in Main Bearings of Marine Engine

■Toward the realization of CBM on main bearings

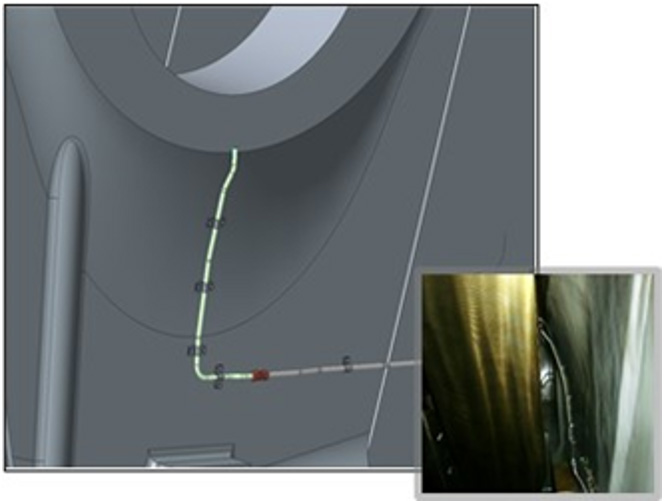

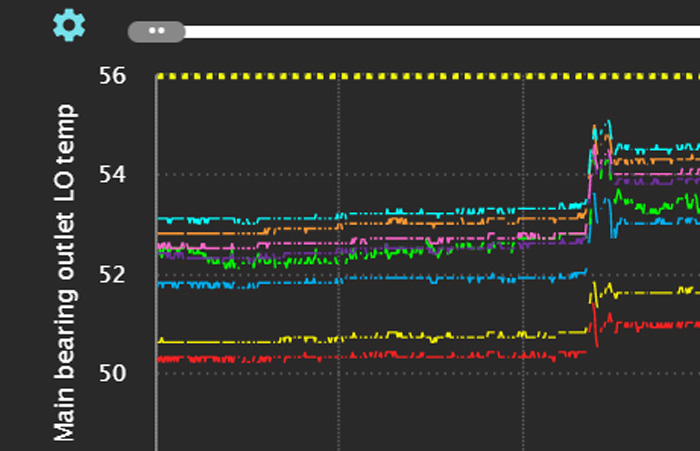

The purpose of this research is to grasp the condition of the main bearings by monitoring the lubricating oil (LO) outlet temperature of the main bearings for materialized Condition Based Maintenance (CBM). In order to materialize CBM by grasping the condition of the main bearings, first, we need to organize how and where failures occur in marine engine plants, what effects they have, and how they are currently being prevented, and then, a risk assessment method was used to examine methods for changing the information to data. This risk assessment method uses Fault Tree Analysis (FTA) to analyze the causes of the failures. For the main engine main bearings to which the CBM method will be applied, we have come to select a method that monitors the main bearing LO outlet temperature, by considering the parameters that can measure the causes based on the results of this analysis. In addition, the possibility of applying CBM was studied by examining whether damage could be properly identified utilizing data measured by sensors installed on actual vessels and by conducting land-based tests simulating the installation conditions in order to verify the certainty of the technology.

■Development of a monitoring tool for actual data

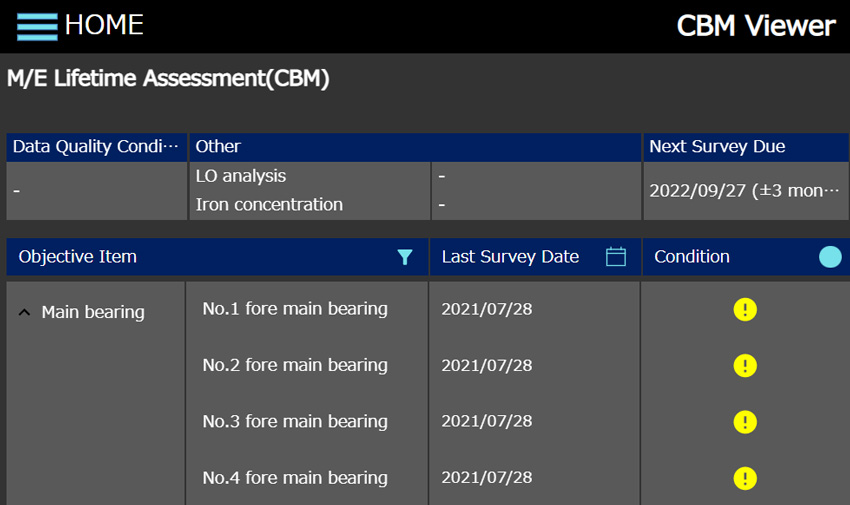

We have developed a diesel engine main bearing condition monitoring device, CBM Viewer, which can acquire detailed bearing LO outlet temperature data by installing sensors in the bearings of large marine diesel engines and ship operation data, and share the data in real time with classification societies and engine manufacturers. This viewer has a function that determines whether or not anomality has occurred based on temperature changes from data obtained from a bearing temperature sensor attached to the diesel engine spindle and displays the bearing condition as a signal, and by sharing the data in real time between shipping companies, classification societies, and engine manufacturers, appropriate actions can be taken in response to detected anomality.

(Writer: Tsuyoshi Tera)

Related Links

ClassNK Technical Report No.5 2022 (I) CBM Life Cycle Maintenance

ClassNK CBM Guidelines [Edition 2.0] (May 2021)

Contact

For additional information about this, please contact us by our inquiry form.