Power System Integration

October 3, 2022

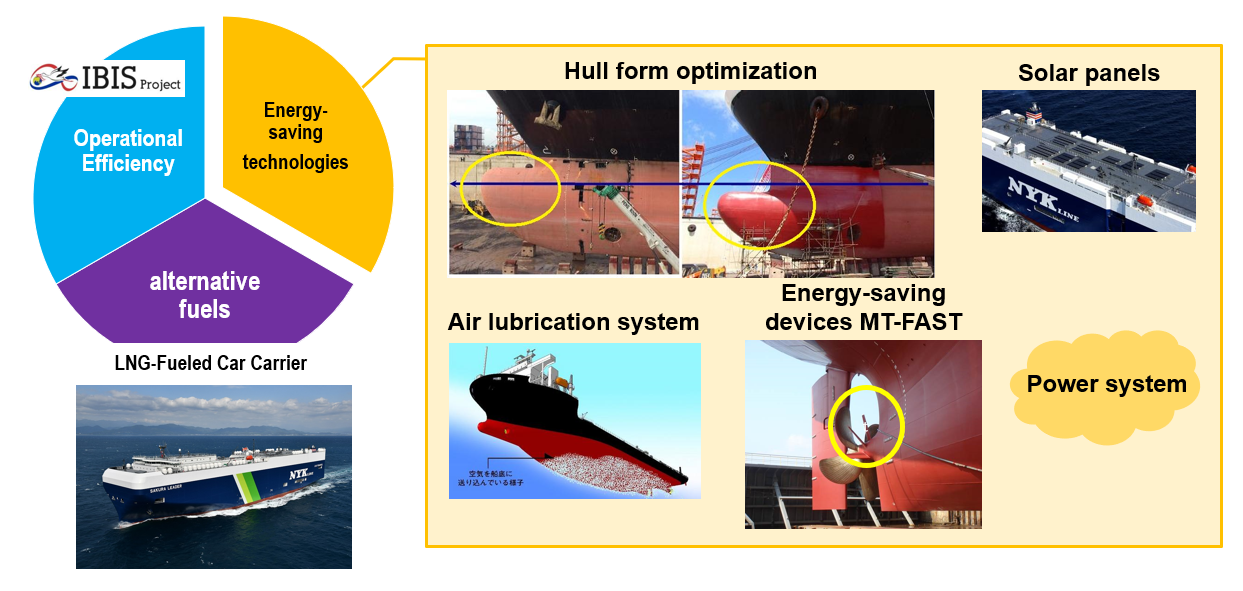

There are three approaches for reducing greenhouse gas (GHG) emissions from ocean-going vessels: “improving operational efficiency through efficient ship operation planning,” “shifting to alternative fuels with lower GHG emissions,” and “introducing energy-saving technologies such as reducing frictional resistance, improving propulsion efficiency through hull modifications, and utilizing renewable energy (Figure 1).

Figure 1) Examples of initiatives to reduce GHG emissions

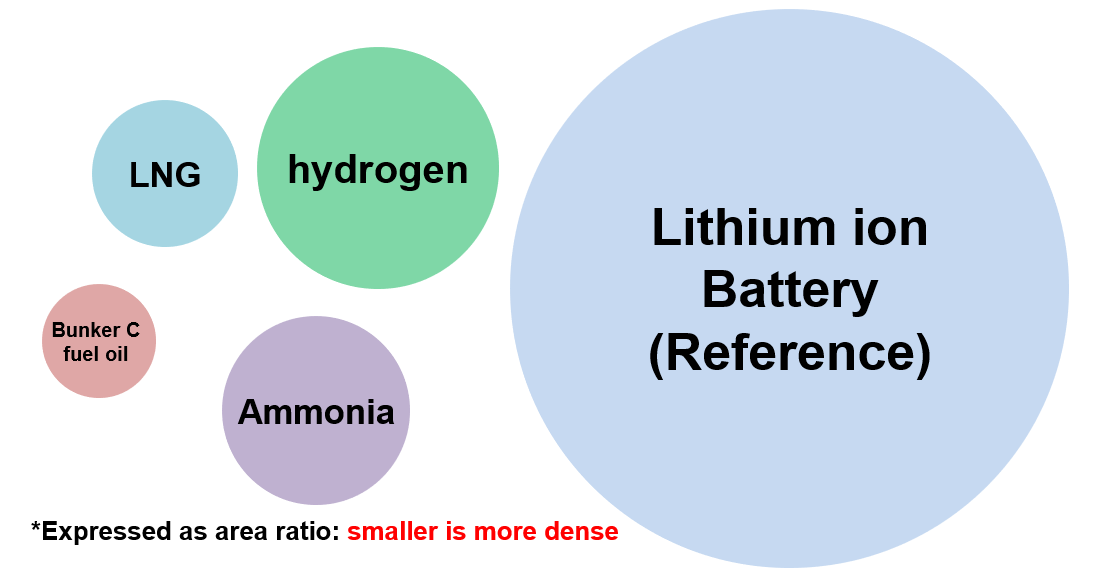

It is often thought that all GHG reductions can be realized if GHG emissions are reduced to zero with alternative fuels, but the alternative fuels that are leading candidates for achieving zero emissions in ocean-going vessels have a lower energy density than conventional heavy fuel oil (Figure 2), so in order to maintain the current hull shape and speed, it is necessary to reduce cargo space and increase fuel tank size, or to consider reducing the endurance. Since these are negative for cargo transport, support through the introduction of energy-saving technologies can be very effective.

Figure 2) Alternative fuels – image of energy density

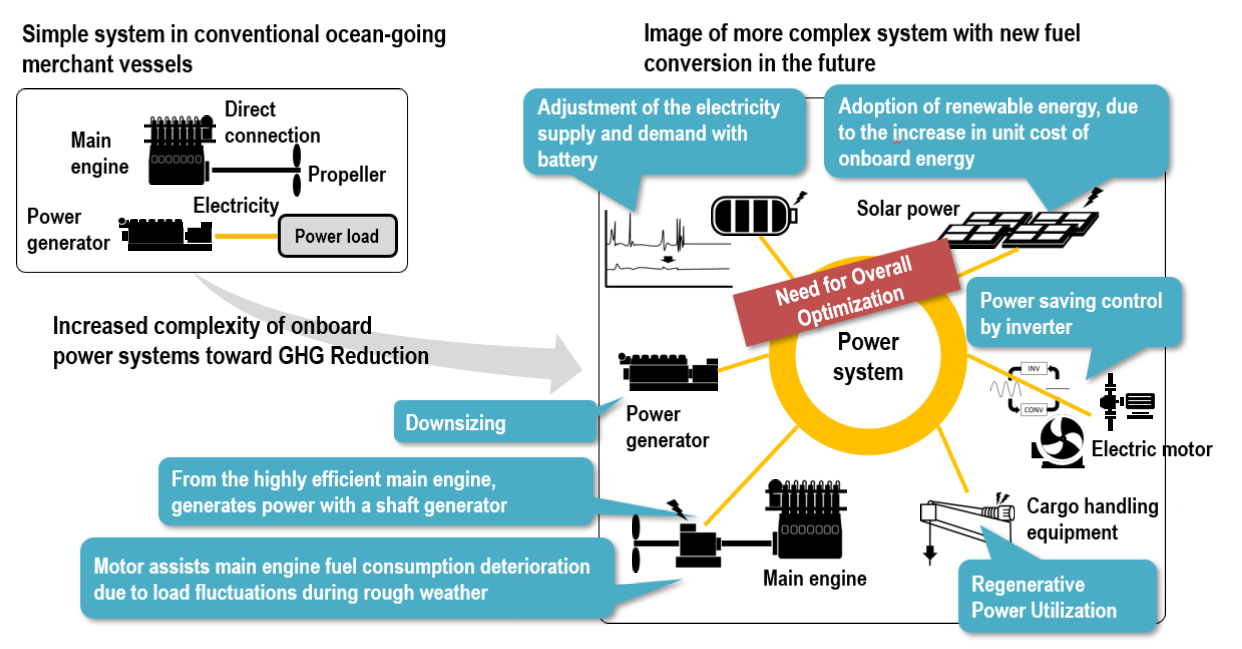

Accordingly, various energy-saving technologies for electric power are being developed, and it is expected that a combination of these energy-saving technologies will be installed in the future to pursue GHG reduction. With the installation of various systems, the power system is expected to become more complex than the simple configuration of a conventional ocean-going ships, and a system that performs overall optimization will be required.

Figure 3) Complexity of onboard power systems

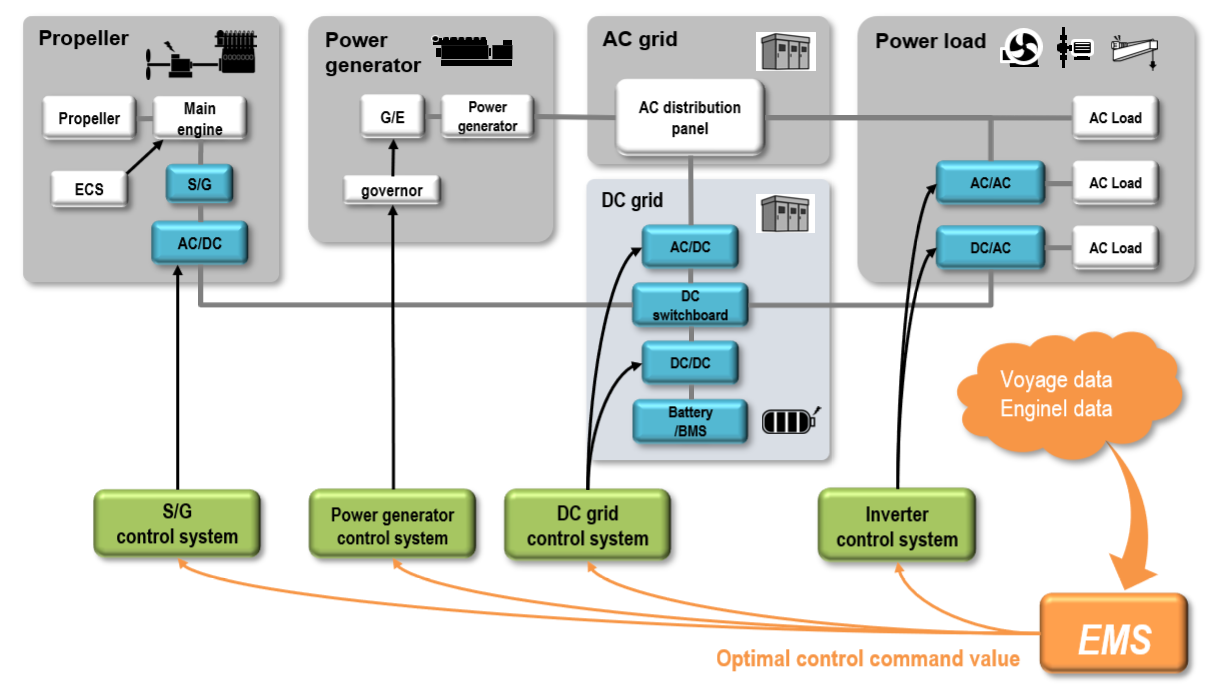

The Energy Management System (EMS) is an overall optimization control system that is responsible for calculating optimal control command values for each control system to minimize GHG emissions using onboard IoT data such as voyage data and engine data, and providing these values to each control system (Figure 4). To realize EMS, we consider that it is necessary to separate the function of safely controlling the system from the function of considering the total optimization. In addition, since the optimization logic cannot be deployed uniformly to all vessels, but rather must be fitted to the onboard systems and operation plans, we believe it is also important to have an efficient system to carry out this development work.

Figure 4) Image of EMS

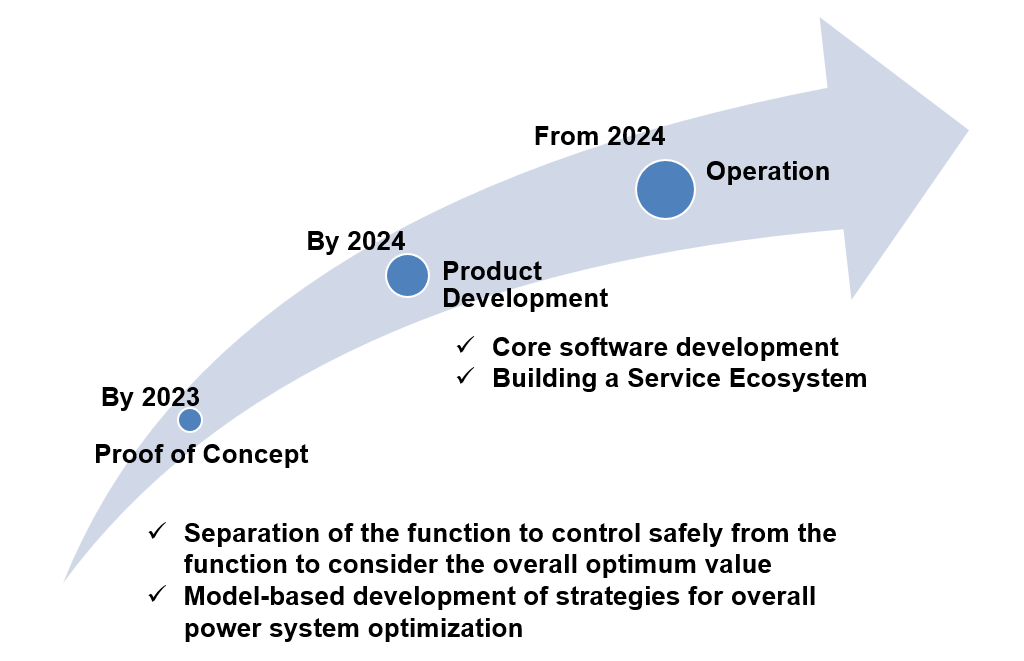

Currently, a concept study for the development of an EMS is being conducted in collaboration with shipyards, equipment manufacturers, and classification societies, and a proof of concept (PoC) for elemental technologies for the full-scale development of an EMS is underway. We plan to complete the PoC for the separation of the function of safely controlling, the function of considering overall optimization and the construction of a model-based development process for total optimization of power management systems by 2023 (Figure 5). Thereafter, product development and the creation of a service ecosystem will follow, with the goal of social implementation by 2025. As a member of the NYK Group, we will continue our efforts to promote ESG management toward our goal of achieving net zero emissions in ocean-going shipping by 2050.

Figure 5) Roadmap for EMS realization

(Writer: Kota Akagi)

Contact

For additional information about this, please contact us by our inquiry form.