MTI Journal

MTI Journal.21

Visualization of Cargo Hold Environment and Efforts to Maintain the Quality of Shipping Cargoes

Yoshio Nakamura

Principal Researcher, Maritime and Logistics Technology Group*

*The job title is as of March 7, 2023

At MTI, various efforts are carried out to contribute to the improvement of cargo transportation quality. As one of these initiatives is to prevent condensation in the cargo holds, maintaining the quality of shipping cargoes.

Background

Cargo care is a fundamental issue in transportation, but because transport by ships requires long hours at sea, the transportation environment changes due to various factors such as daily weather and sea conditions, and it is necessary to respond accordingly according to the situation. Therefore, operating ships are constantly striving to transport cargoes in better condition by utilizing various means.

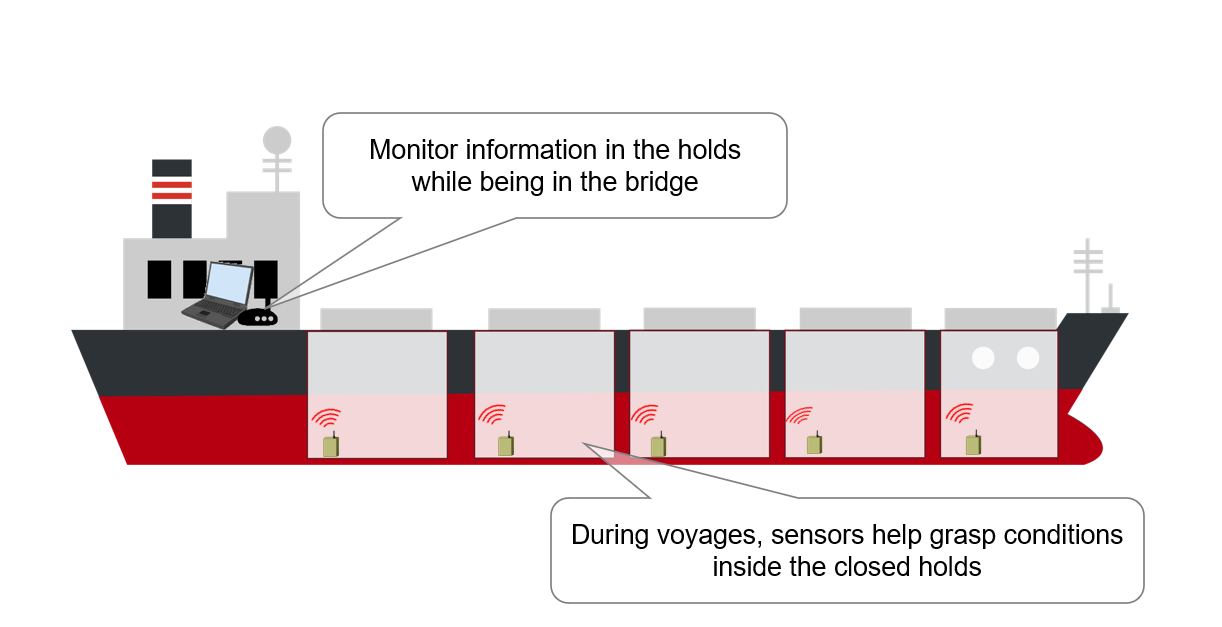

However, the means vary according to ship types and its equipment, and not all ships are equipped with air conditioning, ventilation, etc. In some cases, crew members may make periodic rounds and take measurements using measuring devices to monitor the condition of the holds, and so the operation relies on manual labor to some extent. Meanwhile, turning to technology, sensor and communication technologies continue to develop along with the spread of IoT, and their use is expanding on ships in navigational instruments and engine section equipment. Thus, there is a match between the needs of the operation and the seeds of the technology. This project began with the idea of using these technologies to monitor the status of holds in real time from a remote bridge without having to enter the holds.

Issues

This project is to prevent condensation, so the temperature and humidity in the holds must be monitored to prevent condensation in the holds, and the moisture content in the holds must be controlled appropriately. At first, I did not think it would be that difficult, and thought that by using a temperature/humidity sensor with wireless communication functions, it would be easy to check the condition and avoid condensation by taking appropriate action when it was about to occur. Wireless technology is widely used in various locations on a daily basis, and the communication distance is only a few hundred meters from the farthest hold to the bridge, a distance that can be reached with ease if the wireless communication used is appropriately selected.

However, it is not so easy on ships. In the case of the ship type targeted in this study, the hold is a large box with no power supply and covered with steel walls, and it is a highly sealed area. The radio waves that can be received when the hatch cover, which is the lid of the hold, is open cannot be received from the moment the hatch cover is closed. Wireless communication, which is expected to be able to communicate with the outside even when the hatch cover is closed, consumes a lot of power, making it difficult to operate throughout the voyage unless a large-capacity battery is installed or the measurement intervals are made longer to save sensor operation time. If the measurement interval were to be extended too far, it would be hard to detect when condensation was about to occur, and the measurements would be meaningless.

Inside cargo holds

Seeking Solutions

To find a solution, we first narrowed down the candidate technologies, verified the feasibility of the narrowed-down technologies, and then proceeded to verify the highly feasible technologies through demonstration tests. In narrowing down the candidate technologies, we identified wireless communication technologies with low power consumption and long operation time. To verify the feasibility of the candidate technologies, we conducted a communication verification on board the ship to see if communication from the closed hold to the bridge was possible. With the cooperation of the people on site, we visited the ship while it was at anchor in a port of call in Japan, installed sensors in the holds, and checked whether data can be received near the holds with the hatches closed, and whether the data can reach the bridge.

By proceeding with the verification, we narrowed down the wireless technology to LPWA (Low Power Wide Area), which has the characteristics of low power consumption, long-distance communication, and hardly being affected by obstacles, but on the other hand, the amount of data that can be sent at one time is not that large. This time, the data to be transmitted from holds is temperature and humidity values, so the amount of data is not a concern.

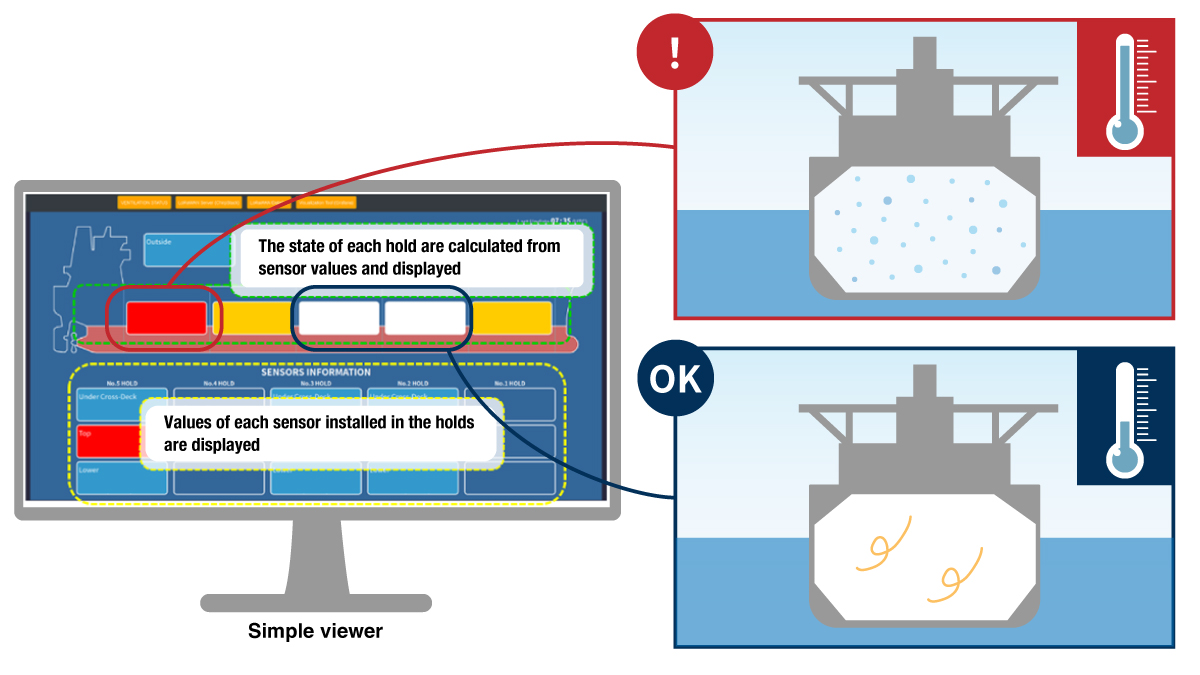

Once the feasibility of the project was confirmed, a study was conducted with a view to actual operation. We identified and studied possible operation methods and conducted demonstration tests on actual voyages accordingly. Sensors were installed at appropriate locations in the holds, and a simple viewer was installed on the bridge to show the status of holds at a glance. This enables crew members to grasp the status of holds in real time on the bridge even when the holds cannot be accessed due to stormy weather etc.

We are now in the process of improving/evaluating the system through verification on multiple voyages. We have received positive feedback from crew members and on-site staff members. We would like to continue the verification through actual voyages to identify problems and areas for improvement that we have not yet noticed, and to eliminate potential factors that could cause cargo damage as much as possible.