MTI Journal

MTI Journal.17

Challenge for Energy Saving through Power System Integration

Takeshi Okamoto

Principal Researcher, Maritime and Logistics Technology Group*

*The job title is as of May 30, 2022

I was seconded to MTI from a marine equipment manufacturer in May 2020, where I am mainly engaged in research on energy-saving technologies related to onboard power. With the global trend toward decarbonization, the development of energy-saving technologies will become increasingly important, along with the shift to alternative fuels with lower GHG emissions and the use of big data to improve operational efficiency. MTI has been researching and practically applying energy-saving technologies such as hull modifications and energy-saving devices. In addition to these, we are pursuing more efficient power generation and power use, with the goal of accumulating as many technologies as possible that can contribute to achieving net zero emissions by 2050.

Energy-Saving Technologies Related to Electric Power

The current general onboard power system is designed to simply cover the output demand of the maximum condition, and therefore, data analysis shows that the system is over-specified and that there is room for efficiency improvement in the low power conditions of slow steaming that have become more popular in recent years.

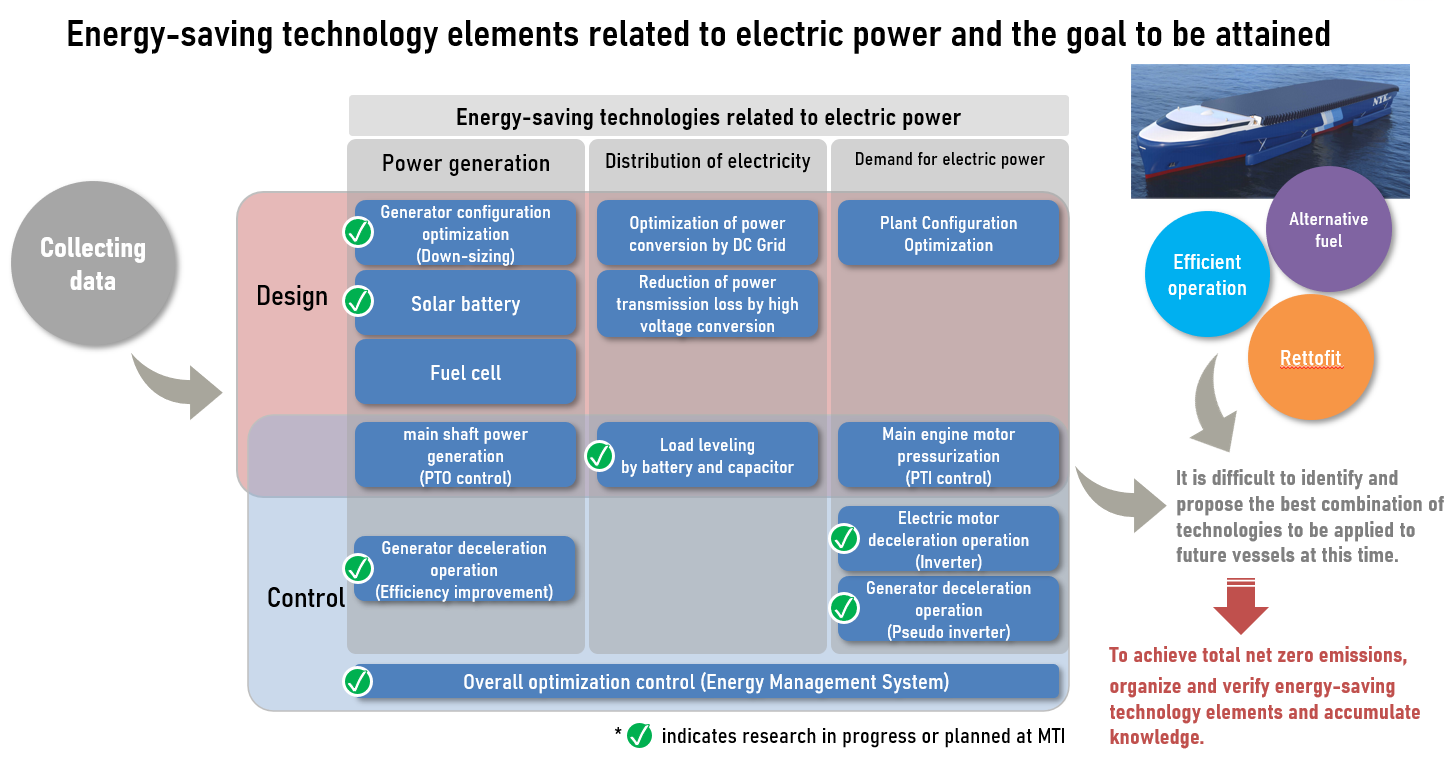

Energy-saving technologies related to electric power can be broadly classified into three categories: power generation, power distribution, and power demand. It is further divided into design technology to arrange the equipment to the appropriate specifications for the ship and technology to control it safely and efficiently according to the operating conditions. Efficient implementation of energy-saving technologies requires complex studies that also take cost-effectiveness into consideration.

Here are a few examples of energy-saving technologies related to electric power. The first is the use of a main shaft generator (S/G). Generally, a main engine with a higher compression ratio is more efficient than a generator engine, and the total fuel consumption can be reduced by extracting power from the main engine through S/G. S/G itself has been used for a long time, but with the spread of S/G with high-efficiency permanent magnet motors and more advanced control, S/G output can be adjusted to smooth out the load on the main engine to improve fuel efficiency and prevent knocking, so it is expected to be used in combination with alternative fuels in the future.

Next is the use of batteries, capacitors, and DC grids. The large-capacity batteries such as lithium-ion currently in widespread use have a low energy density compared to heavy fuel oil, and due to the cost of safety measures and maintenance, it is difficult at this time to convert ocean-going vessels to fully electric propulsion using only batteries, but downsizing generator engines by supporting transitional power demand with small- to medium- sized batteries or capacitors can improve power generation efficiency. In addition, DC grids, which connects DC (direct-current) equipment such as inverters, batteries, fuel cells, and solar cells with DC, are expected to reduce power conversion losses.

Finally, the speed control of the generator engine. Since the load factor/efficiency curve of the generator engine changes according to the rotation speed, varying the rotation speed according to the load factor can be expected to improve efficiency. Moreover, because the speed of the electric motor connected to the AC grid is linked to changes in the speed of the generator engine, the speed control of the generator engine can also be used as a pseudo inverter. In addition to the technologies introduced above, new systems such as fuel cells and the use of renewable energy are also expected to be introduced in the future.

Overall System Optimization

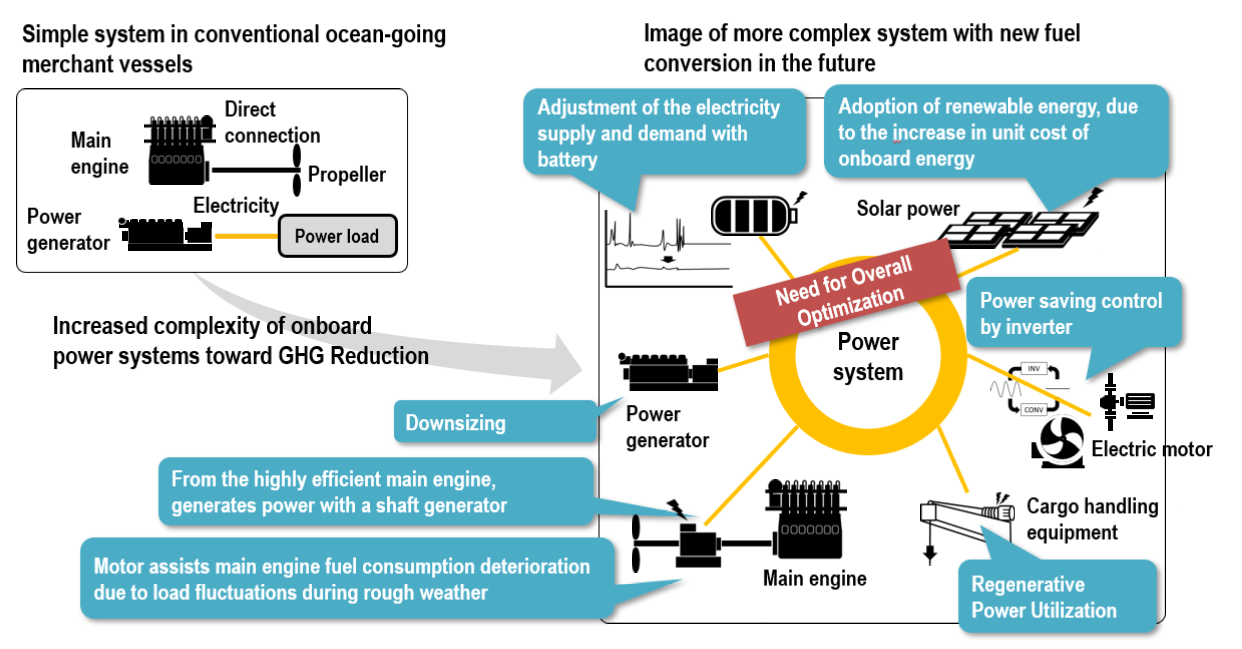

There are various energy-saving technologies for electric power, ranging from those involving large capital investments, such as the use of large-capacity batteries and electric propulsion, to those that are relatively easy to implement, such as improvements through crew operations. And in some cases, each technology is not only effective on its own, but also when multiple technologies are combined to achieve a synergistic effect. While conducting research and studies at MTI, I realized that it is quite difficult to perform overall optimization from the perspectives of both optimal design in accordance with ship specifications and voyage plans, and optimal control in accordance with actual voyage conditions, with considering the ever-evolving performance of each equipment.

Increased complexity of onboard power system for further energy savings

In addition, the existence of system integrators that can provide this kind of total design x control optimization is expected to become more important in the future. However, it is not realistic for a single company to have the necessary knowledge of shipping companies, shipyards, and equipment manufacturers and to provide services in this way. Therefore, I believe that an environment in which shipping companies, shipyards, and equipment manufacturers can work together to achieve optimal design and control will play an important role in realizing net zero emissions in the future.

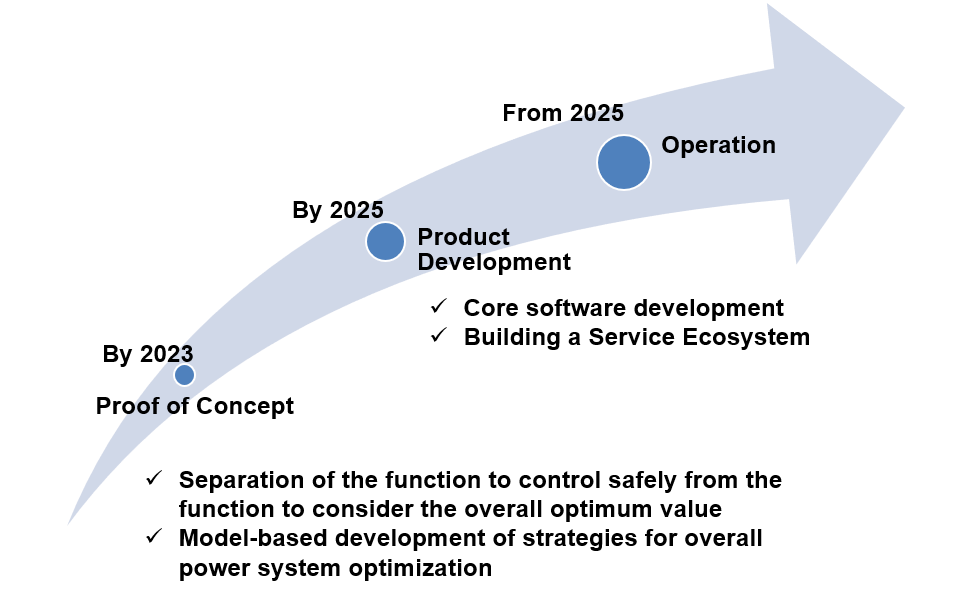

Energy Management System

After developing such concept, for six months from June 2021, we worked with shipyards, equipment manufacturers, and ClassNK to develop an “Energy Management System (EMS),” an environment in which multiple companies can pool their knowledge and experience to achieve optimal design and control. As the study proceeded, we were able to define the functions of the EMS based on the ideas of each company. However, we were unable to reach a conclusion on the service ecosystem because it was difficult to separate responsibilities and distribute benefits in a way that would be acceptable to all stakeholders. But, this discussion enabled us to share a common understanding of the issues and the ideal form of the system, and I think it was a great achievement that we were able to build a cooperative framework for full-scale development. Since February 2022, we have been conducting proof-of-concept testing of elemental technologies for full-scale development of EMS and will continue to work toward full-scale product development and eventual social implementation.

Roadmap for the realization of EMS

Experience at MTI

At MTI, seconded members from various companies, mainly in the maritime industry, come together to cooperate and work on research in a variety of fields. Whenever I encounter that information, I feel the breadth and depth of the technologies related to ships. In addition, I have gained an understanding of the industry structure, shipping-company operations, and problem consciousness that I could not see from the standpoint of a marine equipment manufacturer, and I think I have become able to think with an awareness of essential problem-solving. I will use this experience in my work so that I can provide value to the shipping industry.