SPECIAL INTERVIEW

Energy-saving and CO2 emission reduction have become focused at IMO again

August 29, 2018

Now is the time to improve the ships environment performance

by using the data

Monohakobi Technology Institute (MTI)

Yasuo Tanaka, President

Hideyuki Ando, Senior General Manager of the Maritime Technology Division

The marine industry expects challenges to environment-friendly technologies in its drive to meet new and ever-stricter regulations. In this regard, innovative ships, especially those using digital technology, are highly desired. Even an autonomous ship that was just a dream is now on the R&D agenda at several companies and seems to be creating a lot of momentum in the industry. President Yasuo Tanaka and Hideyuki Ando, Senior General Manager of MTI’s Maritime Technology Division, which handles technological R&D within the NYK Group, were recently interviewed by Kaiji Press (KP) about the current state of and prospects for R&D at MTI.

■Accelerating the utilization of data

– What are the latest topics on technology in the maritime industry?

Tanaka: The loS Open Platform (loS-OP), which is run by the Ship Data Center (ShipDC) subsidiary of Nippon Kaiji Kyokai (ClassNK) and has 46 member companies that include NYK, has kicked into full-fledged operation. The platform itself is still in the “baby phase” and needs to grow in partnership with the member companies. However, we expect that it will lead to an accelerated use of ship data. Discussions related to the sharing of ship data are gaining momentum in Europe as well, so I think that a broad trend to make the best use of ship data has been created on a global basis. The Marine Innovation Panel of the Marine Subcommittee of the Council for Transport Policy, which is under the Ministry of Land, Infrastructure, Transport and Tourism (MLIT), has compiled a report on autonomous ships. We generally agree with the future described in the report, and expect that various projects related to autonomous ships will be launched in the future.

A long-term policy on the reduction of greenhouse gas (GHG) emissions was adopted at the 72nd session of the Maritime Environment Protection Committee (MEPC72) of the International Maritime Organization (IMO), leading the focus of deliberations to shift to CO2 emission reduction again. Now that the 2050 target has been set, we can envision the ideal state for 2030. Having done that, we will have a clearer idea about what needs to be done in the next 10 years to achieve the target, so the entire maritime industry, including the MLIT, will need to deepen deliberations about it henceforth.

Ando: Up until now, we have been committed to saving energy in ships. We project that the burden of fuel costs will grow owing to the upward trend in crude oil prices and the sulfur oxide (SOx) emission regulations that will come into force in 2020, so we are now witnessing a surge in momentum for operational improvements and for hull form modifications that will lead to further fuel economy. With regards to the development of hull form, I think there is still a lot of room for improvement in that area. Environmental consciousness overseas is much higher than what we think it is in Japan. It’s not the case only in Europe, but also in China these days. In this light, we must expect that environmental regulations will be further reinforced in the future.

– What are the important issues on technology for the NYK Group?

Tanaka: We at MTI are advancing full-fledged initiatives toward our next target by using data obtained through the ship performance management system (SIMS) that we jointly developed with NYK. One of our major targets is condition-based maintenance (CBM), and we will advance this together with ship classification societies.

Ando: Promoting the utilization of digital technology in each business unit of the NYK Group is another topic we are tackling. The use of data is not only envisioned to lead to improved efficiency and safety, but is also expected to spread its benefits to such business areas as marketing in the future.

■Evolution of shipping by digitalization

– “Digitalization and Green” has been laid out under the NYK Group’s medium-term management plan. How will the world of shipping change with digitalization?

Tanaka: My definition of digitalization in ships is as follows. A ship moves ahead using the propulsion produced by the main engine, as well as other machinery, and lately, computers are being used to accurately control the timing of fuel injection to optimize combustion and efficiency. A ship’s propulsion system has many components that must work precisely, and traditionally this relied heavily on the craftsmanship of the manufacturer and the operator. But computer-controlled devices of uniform quality are now easier to manufacture and cost less. So as more and more components such as main engines, pumps, and other marine equipment become controlled by computers and run on software, an integration software will be needed to control the individual software of such components. If data communication is added to this, then we will have real loT (Internet of Things). And when that time comes, marine equipment manufacturers, shipyards, and shipping companies will need to think of what they have to do at their respective positions.

Another perspective is the digitalization of logistics procedures. For instance, if we can share logistics information among relevant entities with just the click of a button and shift to a paperless system by communicating contract evidence using block chain and other IT technology, then we can streamline our business process. When it comes to external factors, on the other hand, if digitalization advances in other industries, then the logistics and maritime industry will need to correspond in order to continue as a service provider.

Shipyards have thus far put great emphasis on hull design, but if we can make it easier to modify or convert hull design with the help of data after the vessel has been delivered, then the entire lifecycle of ships will become all the more important. Further, if we can control marine equipment through computers, then even if, for instance, the type of fuel and optimum navigation speed is changed, we might still be able to cope by updating the software of the fuel injection system. Ships’ hulls can be used for 20-30 years, but their ability to adapt to the environmental regulation will be enhanced through the use of software.

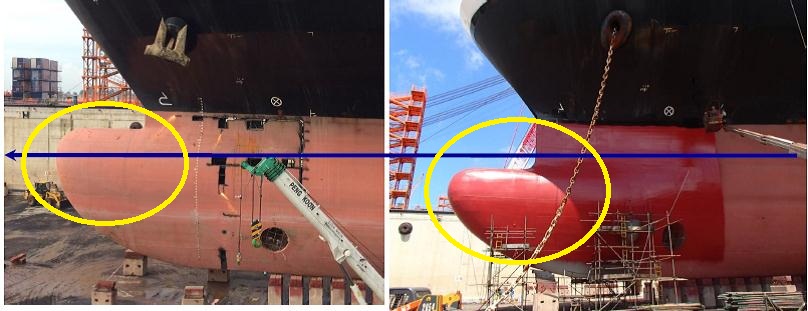

Ando: A ship that was considered a cutting-edge vessel when it was built might become outdated five years later due to regulations or advances of technologies, so I think there will be great potential in ship conversions. We carried out conversions of containerships in 2014 and successfully improved fuel efficiency by as much as 23%. We will probably see such conversions increase for the sake of significantly improving performance or restoring a ship’s competitiveness in the market. Obviously, conversion will incur costs, but if we have reliable ship data, we can use it to simulate the cost-effectiveness of such conversion work with high accuracy.

Remodeling the ship improved fuel efficiency by 23%

(left) before conversion (right) after conversion

Tanaka: If the measurement equipment becomes more advanced, then I think that the existing technologies will be reviewed and modified. The development of ship types has thus far been done through water-tank testing using a model ship, but if we can directly measure such elements as the ocean current around the propellers from existing ships, it could lead to the birth of new innovations.

Ando: That is perfectly embodied by the development of high-efficiency propellers using actual measurement data on a 14,000-TEU containership built by Japan Marine United (JMU) that was recently announced. I think that the ability to measure at actual sea and combining it with simulation technology will boost the progress of technical development significantly. A high-level circulation has been established wherein good-quality data is acquired, leading to the grasping of the next issues to be dealt with, which will then give birth to new technical improvement for addressing such issues.

– How will the development of autonomous ships and remote-controlled vessels progress?

Tanaka: What we are targeting is not the creation of unmanned ships, but a “manned autonomous ship.” I believe that oceangoing ships will not all become unmanned vessels in a single leap.

Ando: I think that the priority is higher for domestic coastal ships that are suffering from a serious lack in manpower. If we think that not a few of the accidents that occur are due to simple oversights in watch-keeping, we can expect a computer that is well suited to monitoring the vessel due to its high information-processing capacity to support humans in these duties. Meanwhile, remote-controlled ships are not impossible, technically speaking, but it will not be easy for them to be put to practical use considering the risk of their becoming uncontrollable in case of a data-communication blackout, or of the ship’s control being hacked by a third party with malicious intent. However, if countermeasures to these threats can reduce risks to acceptable levels, remote control from an onshore operation facility may become feasible. We will come up with various technological options and adopt those economically rational. We need to envision different scenarios based on needs and costs.

– What are the prospects of renewable energy in shipping?

Tanaka: There are studies that suggest a considerable portion of electricity for general household use in Europe will be covered by renewable energy by around 2030, and renewable energy may be able to provide the energy needed by items with relatively small energy consumption, such as automobiles. However, when it comes to ships, aircraft, and other large-size carriers that require enormous power to operate, it might still take a long time before they can operate entirely on renewable energy.

■Expansion of partnerships inside and outside the maritime industry

– What are your thoughts on new partnerships within the maritime industry in the field of technology, or alliances with IT companies and other industries?

Tanaka: While the creation of an open platform like the loS-OP is unusual even when compared to other industries, we still need to exchange information and opinions with the operators of platforms in other industries, as well as watch the trends in other industries. Fostering partnerships with the telecommunications industry will naturally be crucial. Meanwhile, we must also get information on significantly relevant ports/harbors and the logistics industry. The sectors affiliated with ports seem deeply interested in how ships will change in the future. As for coastal ships, I think that the contribution from technical solutions will be big. For instance, if we can develop a technology that will solve the problem of manpower shortage on coastal ships, then it will create huge benefits for society, and the knowledge and experience gained in coastal shipping can be applied on deep-sea shipping in return.

Ando: If we look at the entire society, shipping is just a part of the entire logistic chains. We must be aware that we are being watched from the perspective of how much the environment burden is reduced in the total supply chain, including ports. In that sense, partnerships between ports and logistics are very important. As for the areas that need partnership with IT companies, one such area would have to be cybersecurity. Measures to ensure cybersecurity on ships will become increasingly important, and we must consider total cybersecurity as a whole shipping company group, including ships, of course. With that, we will need to foster alliances different from the partnerships we have built thus far.

– What do you think of international partnerships?

Ando: System integration plays an important role in the present state of technological development. In Europe, the major marine equipment manufacturers lead the technological development; but in Japan, the shipping companies, which are the users, are taking the lead while shipyards and marine equipment manufacturers follow. We may have different approaches due to the difference of social structure, but we cannot make a sweeping judgment on which approach is superior, as they both have their advantages. The directions we are technically targeting are basically similar, so I believe we need to team up by utilizing each other’s strengths.

Tanaka: Europe is already international enough, but Japan is prone to falling into the argument that it has domestic shipping, shipbuilding, and marine equipment manufacturers within the country and therefore does not need to reach outside. We need to be more international in each of those areas. I think that in order to attract excellent talent into our industry, it is important for us to remain technologically challenging and international.

Contents

The NYK Group Tackles the Digitalization Challenge TOP

TOP INTERVIEW, Interview with Tadaaki Naito, President of NYK, – Striving to create new value

Infrastructures of the NYK Group in support of its aggressive stance with data utilization

Digitalization of ships – Challenge of technology development toward manned autonomous ships

Digitalization of navigation – Utilizing data in the field of dry-bulk shipping

Digitalization by collaboration – Pursuing overall optimization through Operation × Hardware